In modern industrial production, efficient material conveying is a key link to ensure smooth production processes. As a widely used and valuable conveying equipment, industrial screw conveyor plays an irreplaceable role in many fields. With its unique design and reliable performance, it provides stable and efficient material conveying solutions for various industrial production.

1. Exploring the working principle

The working principle of industrial screw conveyor is based on the rotation of spiral blades to push the material forward. When the motor drives the spiral shaft to rotate, the spiral blades rotate accordingly, and the material moves axially along the trough or pipe of the conveyor under the push of the blades. The reason why the material can move forward under the push of the spiral blades instead of rotating with the blades is mainly due to the gravity of the material itself and the friction between the material and the inner wall of the trough or pipe. This principle seems simple, but it contains ingenious mechanical design, which enables the material to be stably conveyed under different working conditions.

2. Rich and diverse types

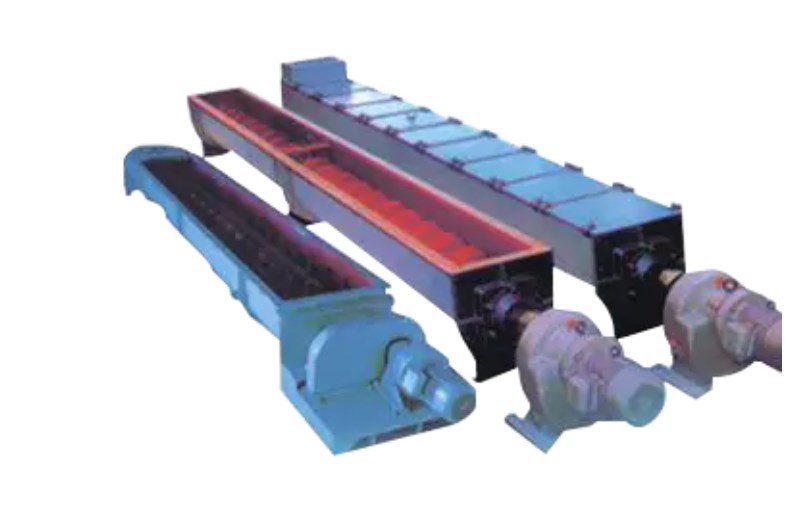

Shafted screw conveyor: the most common type, with a central spiral shaft and spiral blades fixed on the shaft. It is suitable for conveying non-sticky dry powder materials and small particle materials, such as cement, fly ash, grain, etc. Its structure is relatively simple and its conveying efficiency is high. It is widely used in many industrial fields.

Shaftless screw conveyor: There is no central shaft and an integral spiral blade is used. This design makes it particularly suitable for conveying sticky, easy-to-entangle or fiber-containing materials, such as sludge, biomass, garbage, etc. The shaftless screw conveyor can effectively prevent the material from being entangled on the shaft and ensure the smoothness of the conveying process.

Tube screw conveyor: The outer shell is made of seamless steel pipe with good sealing and rigidity. The internal spiral blades rotate with the tube body, and the material rotates and moves forward with the tube body under the action of centrifugal force and friction. Tube screw conveyors are suitable for conveying some materials with high sealing requirements and occasions where they need to be conveyed under specific environments.

Three, a wide range of application scenarios

Chemical industry: In chemical production, it is often necessary to convey various powdered and granular chemical raw materials and products. Industrial screw conveyors can meet the high-precision and high-sealing requirements of the chemical industry for material transportation, ensuring that materials are not contaminated during transportation, while avoiding the leakage of harmful materials that harm the environment.

Building materials industry: The transportation of building materials such as cement, sand, and gravel is an important link in the production process of building materials. With its simple structure and strong conveying capacity, the screw conveyor can efficiently transport these materials to various production stations, providing strong support for the production of building materials.

Grain industry: The transportation of grain needs to ensure the integrity and hygiene of the materials. Industrial screw conveyors can transport grain in a closed environment, reduce the contact between grain and the external environment, prevent grain from being contaminated and attacked by pests, and ensure that grain will not be excessively worn during transportation.

Fourth, significant advantages and characteristics

Simple structure and easy maintenance: The structure of the screw conveyor is relatively simple, mainly consisting of a screw shaft, blades, a trough body, and a drive device. This simple structure makes the equipment highly convenient in installation, commissioning, and maintenance, reducing the maintenance cost and downtime of the equipment.

Good sealing: Whether it is a shaft or shaftless screw conveyor, a sealed trough or pipeline design can be used to effectively prevent material leakage and dust flying. This feature is not only conducive to protecting the environment, but also ensures that the quality of materials during transportation is not affected by external factors.

Flexible conveying direction: The screw conveyor can realize horizontal, inclined or even vertical material transportation, and can be flexibly arranged according to different production sites and process flows to meet diverse production needs.

English

English Español

Español عربى

عربى