In modern industrial production, material handling is a crucial link. Whether it's the transportation of powdered, granular, or small-lump materials, the Industrial Screw Conveyor, as an efficient and reliable conveying equipment, is widely used in multiple industries. Especially in chemical, mining, metallurgy, and food industries, screw conveyors have become an indispensable component in many production lines due to their unique structural design and superior performance.

Working Principle and Structural Characteristics of Industrial Screw Conveyors

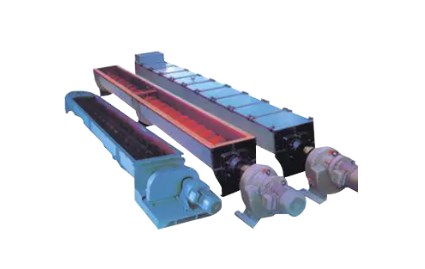

The basic working principle of an industrial screw conveyor is to push materials along a certain trajectory through rotating helical blades, achieving horizontal, vertical, or inclined material transport. The equipment consists of a screw shaft, helical blades, casing, inlet, outlet, and drive device. During operation, materials enter the conveying chamber of the screw conveyor through the inlet, and the rotation of the helical blades pushes the materials along the pipe to the designated location. Due to its simple structure, ease of operation, and maintenance, screw conveyors are widely used in many fields.

The design of screw conveyors not only focuses on the efficiency of material transport but also considers the characteristics of the materials. For example, some materials may be easily crushed or damaged, or prone to clogging during transportation. Therefore, the design of industrial screw conveyors usually considers different helical blade shapes and materials, and selects appropriate helix angles and pipe diameters to ensure smooth material transport.

Advantages of Industrial Screw Conveyors

Compared with other types of conveying equipment, screw conveyors have several significant advantages. The design of screw conveyors is flexible and can be customized according to actual needs, adapting to materials of different shapes, sizes, and physical properties. Whether in horizontal or vertical conveying situations, screw conveyors can provide relatively stable material flow, avoiding material dropping or clogging that may occur with traditional conveying equipment.

Screw conveyors have a compact structure and occupy less space, making them very suitable for space-constrained environments. For example, in a production line, screw conveyors can work closely with other equipment to efficiently complete material handling tasks, thereby improving production efficiency.

In addition, screw conveyors are highly adaptable and can operate stably in a variety of working environments. Spiral conveyors perform excellently in various environments, including high temperatures, low temperatures, high humidity, and dusty conditions. Furthermore, spiral conveyors have a long service life, especially under proper use and maintenance conditions, enabling long-term stable operation and reducing production costs for businesses.

Applications of Spiral Conveyors

Industrial spiral conveyors have a very wide range of applications, covering almost all industries that require material handling. In the chemical industry, spiral conveyors are often used to transport fertilizers, powdered chemicals, and plastic granules. In the metallurgical and mining industries, they efficiently transport ores, coal powder, and other raw materials, ensuring the stable operation of production lines.

Spiral conveyors also play an important role in the food industry. For example, in flour processing and feed production, spiral conveyors enable precise material handling, ensuring smooth production processes. Due to their diverse materials and structures, spiral conveyors can also meet the requirements of different materials in terms of hygiene, safety, and corrosion resistance.

In the cement industry, spiral conveyors are mainly used to transport cement, fly ash, mortar, and other materials. Due to the complex production environment in the cement industry, spiral conveyors are usually designed with wear resistance and corrosion resistance in mind to ensure long-term efficient operation.

Choosing the Right Industrial Spiral Conveyor

Although spiral conveyors have a wide range of applications, to select the appropriate equipment and ensure its optimal performance, businesses need to consider many factors. Material characteristics are one of the most critical factors in selection. The particle size, fluidity, and corrosiveness of different materials will all affect the design of the conveyor. For example, materials with poor fluidity may require a more enclosed conveying environment, while highly viscous materials require specially designed blade shapes to prevent clogging.

Conveying distance and conveying capacity are also important factors to consider when choosing a spiral conveyor. If long-distance conveying is required, it may be necessary to consider increasing the power of the spiral conveyor to ensure that the material can be smoothly transported to its destination. When handling large volumes of material, the stability and efficiency of the equipment must also be ensured.

Finally, the ease of maintenance and upkeep is also an aspect to consider when choosing a spiral conveyor. To improve equipment operating efficiency and extend its service life, regular cleaning, lubrication, and inspection are necessary. Therefore, choosing an easy-to-maintain screw conveyor is crucial for ensuring the long-term stable operation of the equipment.

Frequently Asked Questions (FAQ)

1. How long is the service life of an industrial screw conveyor?

The service life of a screw conveyor is closely related to its working environment, material characteristics, and daily maintenance. Under normal use and maintenance conditions, the lifespan of a screw conveyor can reach several years or even longer.

2. How to choose a suitable screw conveyor model?

When choosing a screw conveyor, it is necessary to first understand the fluidity of the material, particle size, and whether it contains corrosive components. Secondly, the conveying distance and flow rate requirements, as well as equipment installation space limitations, should also be considered.

3. Can screw conveyors handle wet or sticky materials?

Screw conveyors can handle wet or sticky materials, but it requires designing appropriate screw blades and conveying pipes based on the specific material characteristics. For example, screw blades with scrapers can be chosen to prevent material from sticking to the pipe wall.

4. What daily maintenance does a screw conveyor require?

Daily maintenance of a screw conveyor mainly includes cleaning the equipment, regularly checking the operation of the screw blades and motor, and lubricating the bearings. Regular maintenance helps extend the equipment's service life and reduce malfunctions.

5. Are industrial screw conveyors noisy?

Screw conveyors are generally low-noise, but the noise may be more significant when handling certain high-flow or hard materials. To reduce noise, sound insulation facilities can be installed or a low-noise drive unit can be selected.

As an important material conveying equipment, industrial screw conveyors are widely used in various industries due to their high efficiency, flexibility, and reliability. In the selection and use process, reasonable design, regular maintenance, and a thorough understanding of material characteristics are key factors in ensuring optimal performance.

English

English Español

Español عربى

عربى